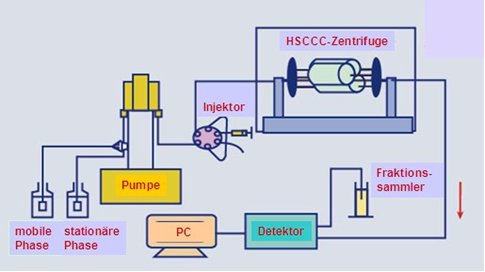

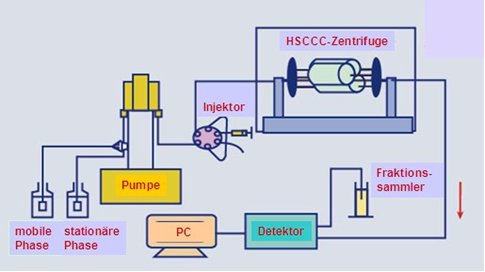

Figure 1: Schematic structure of a CCC-System

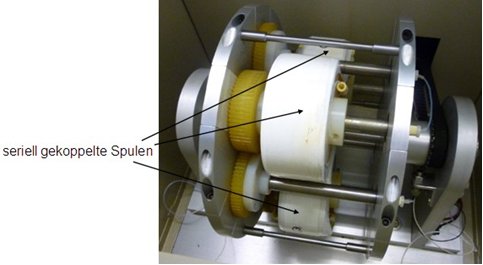

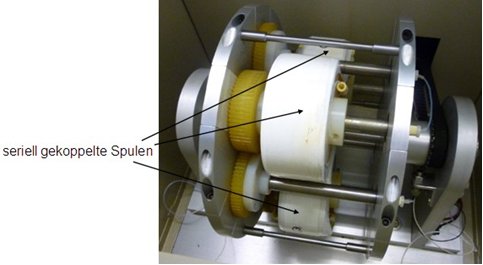

Figure 2: Picture of the three coils with a serial coupling installed in a CCC-Centrifuge

The Countercurrent Chromatography (CCC) is a separation technology that was developed in the late 1960s, which unfortunately to this day has reached a relatively low awareness level amongst the analysts. The CCC takes advantage of the distribution processes between two immiscible liquid phases [Ito & Bowman, Science 167 (1970) 181]. The separation is based on the different affinity of the sample components in the phases, but not on the effects of adsorption as in the case of high performance liquid chromatography (HPLC) or column chromatography. With the CCC no solid stationary phase is being used, and therefore an irreversible adsorption of sample components as well as the risk of degradation of samples on active surfaces in the System are eliminated.

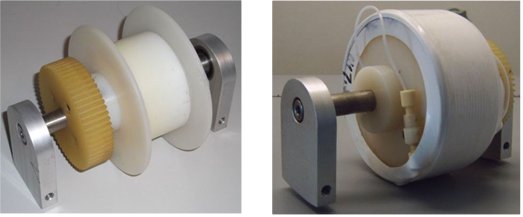

In the early 1980s Ito introduced the so-called type-J planetary centrifuge, and since then, this technology is used by default in commercial devices. These hydrodynamic devices hold the stationary phase inside a planetary moving coil while the mobile phase is pumped through the system. The key element of an CCC-system (Figure 1) is a multi-layer coil. A multi-layer coil consists of several layers of PTFE tubing wound around a coil. Typically three or more of such helical coils are connected with a serial coupling and integrated into a centrifuge in such a way that all coils are at the same distance from the central axis of the centrifuge and their longitudinal axes are parallel to the central axis (Figure 2). The coils arranged inside the centrifuge rotate in a planetary motion, which means they revolve around the central axis of the centrifuge and simultaneously with the same angular velocity (ω) and in the same direction about their own rotation axis. This

particular arrangement eliminates any twisting of the tubing connections between the single coils and the central axis during the planetary motion [Y. Ito, J. Chromatogr. A 1065 (2005) 145-168].

|

|

| Figure 1: Schematic structure of a CCC-System |

Figure 2: Picture of the three coils with a serial coupling installed in a CCC-Centrifuge |

During an CCC- fractionation this motion has two main functions. The planetary motion ensures that the mobile phase is eluted continuously through the separation column without any loss or contamination. Furthermore, a specific hydrodynamic flow of both liquid phases inside the multi-layer coil is generated.

Two immiscible liquid phases are injected in a rotating coil with closed ends and this rotary motion causes a complete separation of the two phases along the length of the coil. The CCC effectively just carries the mobile phase through the system, whilst the stationary phase is retained within the coil [Y. Ito, J. Chromatogr. A 1065 (2005) 145-168].

Through the planetary motion, permanent changing forces work on the mobile and the stationary phase, resulting in frequent mixing and separation processes in the separation tube and the inside of the coil is divided into two parts (mixing and separation zone). Since each mixing zone flows through the coil with a speed of one rotation per revolution around the central axis, the large number of zone sequences cause a large phase-interface, at which many partitioning equlibriums take place while the samples are transported through the system, achieving a high separation efficiency [Y. Ito, J. Chromatogr. A 1065 (2005) 145-168].

Nowadays the CCC is regarded as an efficient preparative separation technology and is used generally for the isolation and filtration of different natural and synthetic products [Y. Ito, J. Chromatogr. A 1065 (2005) 145-168].

The CCC process is based on the use of a two-phase solvent system instead of defined solid column material used for example in conventional chromatographic separations. The solvent system consists of two immiscible phases, one of which is used as a stationary phase and the other as mobile phase. The search for a proper solvent system for the target compound(s) is the most important preparatory work for a successful application of the CCC. In order to find a proper solvent system it should meet the following requirements [Y. Ito, J. Chromatogr. A 1065 (2005) 145-168]:

The flow rate of the mobile phase, which is determined by the upstream pump, defines the separation time, the retention of the stationary phase and thus also the peak resolution. Low flow rates increase on the one hand the retention of the stationary phase and thus improve the Peak-resolution, on the other hand they prolong the separation time. Longer separation time means wider peaks.

After all the unit parameters of the CCC should be optimized as to different purposes of use, taking all influencing factors into account.

Figure 3: Picture of the CCC-Coils (left) without and (right) with wound PTFE tubing

The efficiency of the CCC is on the one hand up to the large sample capacity (our system: 0,5-1 g) on the other hand up to the possibility to isolate natural substances from food or plants. For more complex issues our proposed two-stage method has proven itself [Schröder & Vetter, J. Chromatogr. A 1237 (2012) 96-105]. It is based on (1.) an enrichment step followed by (2.) an isolating step.

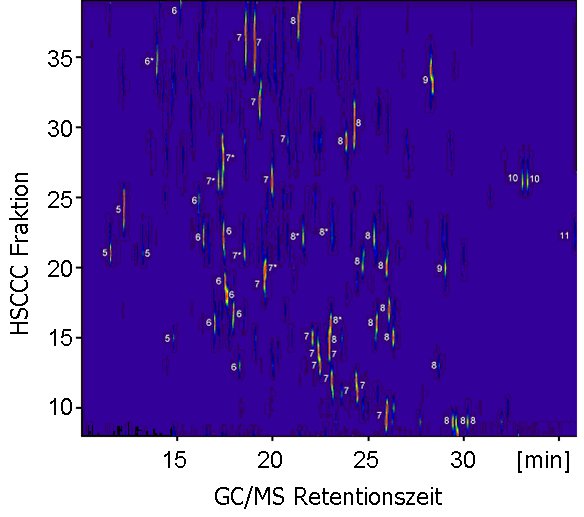

The enrichment step is based on the CCC fractionation of the sample (extraction of e.g. 30 fractions). These then are examined thoroughly by means of GC/MS. We succesfully use this technique already in the field of polyhalogenated compound [Kapp & Vetter, J. Chromatogr. A 1216 (2009) 8391-8397][Vetter et al., Chemosphere 84 (2011) 1117-1124], phytosterols [Schröder & Vetter, Anal. Bioanal. Chem. 400 (2011) 3615-3623] [Schröder & Vetter, J. Chromatogr. A 1237 (2012) 96-105] and fatty acids [Li et al. Chromatographia 75 (2012) 1-6][Schröder & Vetter, J. AOCS 90 (2013) 771-790. Due to the good distribution of the compounds in the single fractions the GC/MS-analyses allows the identification of many compounds, which are not detectable without CCC fractionation. By linking the data in a 2D-plot structural coherences and differences within a substance class can be revealed (Figure 4):

Figure 4: 2D-Contourplot of the CCC fractions (Y-axis) over the GC/MS retention time (X-axis) the most important components of the chlorinated pesticide Toxaphene. The numbers indicate the chlorination degree [Kapp & Vetter, J. Chromatogr. A 1216 (2009) 8391-8397].

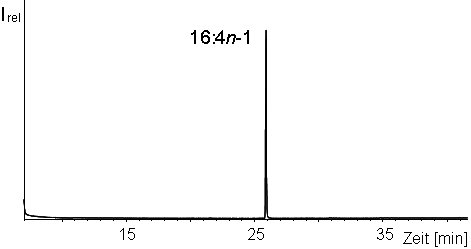

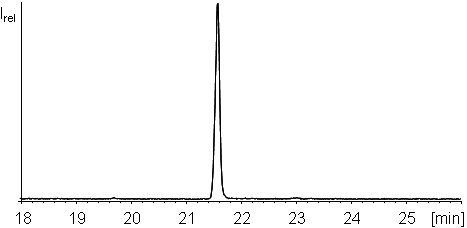

From the fractions of the enrichment step the ones containing interesting compounds can be selected. In doing so, fractions can also be combined. In that way we were able to isolate several fatty acids [Li et al. Chromatographia 75 (2012) 1-6] (Figure 5) and phytosterols [Schröder & Vetter, J. Chromatogr. A 1237 (2012) 96-105] (Figure 6) and also polyhalogenated compounds in pure form. Therefore the CCC has become an important tool for both substance classes (lipid components and polyhalogen compounds), on which our research is primarily focused on.

|

|

| Figure 5: GC/MS chromatogram of the rare fatty acids 16:4n-1 (with a terminal double bond) isolated from fish oil by means of the CCC [Li et al. Chromatographia 75 (2012) 1-6] |

Figure 6: GC/MS chromatogram (measured as trimethylsilyl ether) of campestanol isolated from vegetable oil by means of the CCC [Schröder & Vetter, J. Chromatogr. A 1237 (2012) 96-105] |